Sep. 16, 2020

1. The definition of "small umbrella" rubber

Rubber: refers to a highly elastic polymer material with reversible deformation. It is elastic at room temperature and can produce greater deformation under a small external force. After removing the external force, it can return to its original shape. Rubber is a completely amorphous polymer, its glass transition temperature (T g) is low, and the molecular weight is often large, more than several hundred thousand.

Rubber is divided into two types: natural rubber and synthetic rubber. Natural rubber is processed by extracting gum from rubber trees, rubber grass, and other plants; synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in all aspects of industry or life.

Raw rubber (raw rubber is a kind of rubber that has not undergone any processing) needs to be vulcanized to cause the rubber macromolecules to undergo chemical reactions at a certain temperature, pressure, and time to produce cross-linking, so that the rubber compound can be converted into vulcanized rubber. It will have better physical properties, and the linear structure between rubber molecules becomes a three-dimensional structure.

This process involves formula design, plasticizing, mixing, molding, and curing processes.

2. Application of rubber in the automotive wiring harness industry

When the electronic and electrical components in the wiring harness system pass through the car door body, custom rubber components can prevent the electronic and electrical components from being damaged and maintain the airtightness after passing through the object, and at the same time play a role in wear resistance, waterproof, and sealing. .

3. General characteristics of rubber parts

Features of EPDM

1. Aging resistance, good weather resistance, excellent electrical insulation, chemical resistance, and impact elasticity

2. Wide operating temperature range, -55℃~120℃ long-term work, the highest operating temperature is 150℃

3. Resistant to rain and other liquids in the atmosphere, and can avoid long-term cracking in the natural environment of sunlight, humidity, high and low temperature

4. Good elasticity can withstand multiple fatigue exercises and can recover from multiple deformations in various environments.

The maximum operating temperature of the EPDM rubber is 150°C. Silicone rubber (VMQ) is used at high temperatures. Silicone is generally divided into liquid silicon and solid silicon. The operating temperature range of silicone rubber (-60 ℃~300℃)

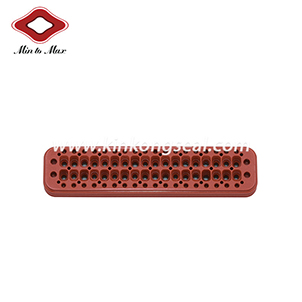

Custom Rubber Components

4. Rubber parts processing

Weighing, plasticizing, mixing, mixing, collecting, quick inspection, preforming, vulcanization, repair inspection, packaging

5. Formula design

Formula design is the most critical step for rubber parts, and it is also the treasure of the famous rubber parts manufacturers. It is also the key to the supply capacity of major rubber parts. Each company's formula is basically different.

The formula design is to select raw materials reasonably according to the performance requirements and process conditions of the rubber product, and determine the ratio of the amount of various raw materials, so that the physical properties, processability, and cost of the rubber material can achieve the best balance.

The purpose of rubber formula design is to make the best overall balance of performance, cost and process feasibility of rubber products.

Generally follow the following principles:

1. Fully understand the performance requirements of the product and the use environment (the performance of the semi-finished product during the design process should generally be higher than 15% of the finished product index)

2. Since the performance of rubber products is generally multifaceted, it is necessary to grasp the main requirements and balance the secondary requirements

3. For multi-component products, consider the overall

4. Balance use performance and processing performance

5. Consider the interaction between the compounding agents

6. Low pollution

7. Reduce costs

Conventional formula composition

1. Raw rubber (single use or combined use of polymer): matrix material or matrix material

2. Vulcanization system: A system that chemically interacts with rubber macromolecules, transforms the rubber from linear macromolecules into a three-dimensional network structure, improves rubber performance, and stabilizes its shape.

3. Reinforcing filling system: adding reinforcing agents such as carbon black or other fillers to rubber to improve its mechanical properties, improve process performance, and reduce product costs

4. Protection system: adding antioxidants to delay the aging of rubber and prolong the service life of products

5. Plasticizing system: reduce the hardness of the product and the viscosity of the rubber compound, and improve the processing performance

6. Processing and functional additives: improve the processing and physical properties of rubber compounds

The basic process of formula design

1. Research

The use conditions of the product, such as temperature, pressure, contact with medium, frequency of use, etc.

2. Material selection

According to the survey results, determine the basic formula, including raw rubber materials, various compounding agents, etc.

3. Formula

Verify and determine the test method that can reflect the product performance, and repeat the experiment to screen

4. Inspection

Prepare rubber materials and products through selected formulas for verification

5. Set process

Draw up processing conditions according to the test process

6. Evaluation

A comprehensive evaluation of product performance, cost, and process

We are a Silicone Single Wire Seal manufacturer. If you are interested in our products, please feel free to contact us.

Tel: +86 13705057546

E-mail: info@kinkong.com

Add: #27 Hengjing Xiyi Road, Liushi Town, Yueqing City, Zhejiang Province, 325604, China.

Copyright © Min To Max All Rights Reserved |